Had that been the case (it was not), a request to Avid to extend that capability to a user definable XY location for tool changes for "normal" 3 axis work might have been easy. In one of Avid's Youtube videos explaining the set-up of their 4th axis, I thought I remembered seeing such a routine.

#Cnc touch plate manual#

Given that I will probably use their 4th axis (also made functional in their version of Mach4), I'll probably stick with it.Īnother post in this thread asked if there was a routine where the touch plate could be used in a fixed position (a fixed reference point) presumably to facilitate manual tool changes called during a machining operation (I hope I got that right). I chose to down load a demo of Avid's Mach4.

#Cnc touch plate code#

The response from Avid was that the code is now "baked in" to their copy of Mach4 and the "cut and paste" approach possible with Mach3 wouldn't work. Exactly what I ask of Avid directly in recent months as I have their plate, but hadn't set up Mach4 yet (I've never run Mach3 - my CNC is in progress). Information on the CNC Router Parts website of old detailed how a bit of code could be applied to an existing copy of Mach3 to allow Avid's device to work on other systems. I'll attempt to clarify and respond to the original post from this thread What was asked (I believe) was if the Avid tool touch plate could be made functional in Mach4 from Artsoft. I believe it is the TouchOffHelp.PDF file. I believe there is some info about Touch module in the Mach4 docs subdirectory. If you are like me, the only routines you are likely to use with any regularity will be the center finding (the circle above that looks like cross hairs) and the Z=0 function (lower right hand corner). The generic Mach4 Touch screen will allow you to fully use the Avid plate. What's special is some macro and screen modification Avid did. The Avid Touch Plate is not special, in so far as the way it is set up and used. Here's a screen print of the Touch Screen: It's all built into a Mach4 canned macro. Pressing the "Touch Button" will open a screen where you set your probe feed rate, offsets, and execute various touch moves. The box corresponding to the way you added your probe will turn on upon contact. Under the blue screen, see the button called "Touch." Also, see the 4 little boxes above it. Here's a screen shot of the Mach4 screen: You can just use Mach4's "Touch" subscreen. I know they have done their flavor of Mach4 but I really do not want to redo it all over! Bill, I don't believe you need a "routine" to run Avid's touch plate.

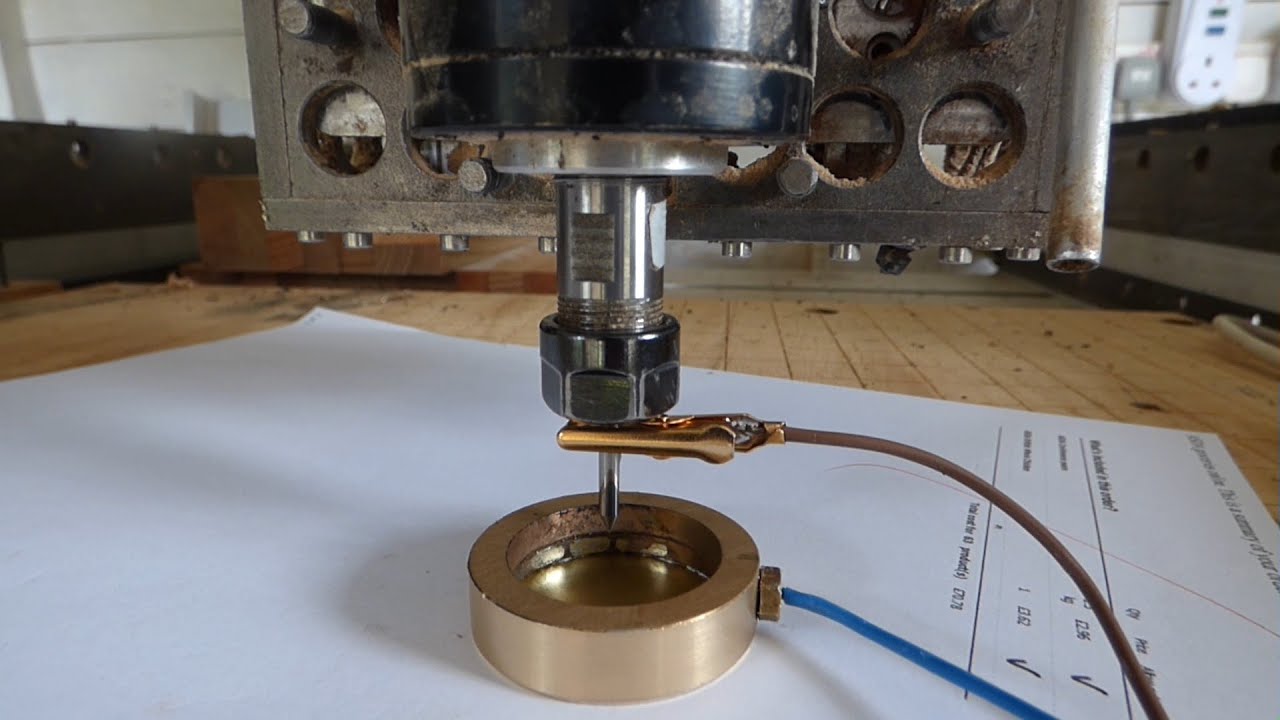

Is there a add in or plug in, macro to add the CNCRP touch plate routine to my un-official Mach4? I have emailed them but no response so far, and I assume they are busy as usual. The system is 1.5 years old but had been running on Mach3, Thanks to GME and others I switched it over last fall to Mach4. This procedure can be used when a drill is changed.I have a Plug and Play NEMA 34 system on my FLA 48x48 router. I do not use the program yet (discovered its existence yesterday), but I think the best would be to create this procedure as XYZ probing, and leave the current procedure as Z probing. G91 G0 Z3.175 # goes to the Z end position 3.175mm over the piece G92 Z20.32 # when find Z, Z0=20.32 (Touch Z Axis Thickness): G38.2 Z-25.4 F76 # search for Z position of touch with feed of 76 (initial Z must be <= 25.4mm) G91 G0 Z24.07 # returns Z to stay in position (over the piece) (initial Z = 24.07mm) G91 G0 Y03.175 # returns to disengage the Touch (Y=3.175) G38.2 Y-25.4 F76 # search for Y position of touch with feed of 76 (initial Y must be <= 25.4mm) G91 G0 X-25.4 # forward X to stay in position (behind the piece): X = 12.7 - 25.4 = -12,7mm

G91 G0 Y25.4 # returns Y to stay in position (behind the piece) (initial Y = 25.4mm) G91 G0 X12.7 # returns to disengage the Touch (X=12.7) G38.2 X-12.7F76 # search for X position of touch with feed of 76 (initial X must be <= 12.7mm) Desire Feed: 76 mm/min Bit Diameter: 3.1750 mm Touch Z Axis Thickness: 20.3200 mm Touch X Axis Width: 50.8000 mm Touch Y Axis Width: 50.8000 mm

0 kommentar(er)

0 kommentar(er)